The Workshop on “IBM Technologies for the Digital Enterprise” - IBMTEC

The objective of this workshop is to organize a 2-day international academic meeting on "IBM Technologies for the Digital Enterprise" (the Digital, Contextual Enterprise of the Future), presenting the latest technologies and software tools developed by IBM, and which should be used today in the Manufacturing Value Chain (MVC) – integrating manufacturing structures, robotic workstations, supply chains and transport facilities. This Workshop is organized for teaching and research staff from engineering and business faculties of universities working close with IBM in higher education and scientific research.

The Workshop aims at presenting the main trends and challenges in the management and control of robotized manufacturing enterprises and integrated supply networks, and the methods, solutions, technologies and tools developed by IBM that can be used to solve these challenges: Cloud models; virtualization and optimal workload allocation in MES; big data for business analytics, optimization and predictive maintenance; SOA for Manufacturing Integration Framework (MIF) and QoS monitoring, mobile applications for Intelligent Products (IP), product-driven control; digital marketing; CRM and Supply Chain Management.

Manufacturing companies will also need to build the capabilities required to manage big data. Despite the fact that this sector has been dealing with large datasets for two decades, the rising volume of data from new sources along the supply chain and from end markets requires a new level of storage and computing power and deep analytical expertise if manufacturers are to harvest relevant information and insights. There is a shortage of talent with the right experience for managing this level of complexity; this represents one strong motivation for organizing this Workshop. The second reason is presenting to universities IBM technologies related to big data, analytics for production planning and supply chain optimization, resource virtualization and cloud services for sustainability, service orientation for production tracking and preventive resource maintenance, and mobile apps for product driven automation and after-sales services.

The Theme of the IBMTEC Workshop

The “Factories of the Future” partnership identifies and realises innovation-driven transformations in manufacturing sectors by pursuing a set of development priorities along the following research and innovation domains:

- Total enterprise integration: the Manufacturing Integration Framework (MIF) linking business processes with production and supply processes

- Advanced enterprise management

- Adaptive and smart manufacturing systems

- Digital, virtual and resource-efficient enterprises

- Monitoring, diagnosis and maintenance in process control

- Collaborative and mobile enterprises

- Human-centred manufacturing

- Customer-focused manufacturing

In this actual global development context, the mission of higher education is to study and teach the overall enterprise architecture and core technologies to establish a comprehensive, Internet-scale platform for networked management and production that will encapsulate the right abstractions to link effectively and scalable the various stakeholders (production firms, manufacturing plants, material and component providers, technology providers, key services) to enable the emergence of a feasible and sustainable Internet economy for industrial production. This accomplishment of this mission is currently based on three viewpoints:

- VP1. Smart Enterprise: Novel controls based on ICT convergence in mixed batch planning and product scheduling, automation, robotics, quality control, environment and resource instrumenting.

- VP2. Digital Enterprise: Novel operations based on product and process modelling, management and simulation, including field operations.

- VP3. Virtual Enterprise: Novel management of complex supply chains across production sites and including logistics and material flows across the product life cycle, including field operations

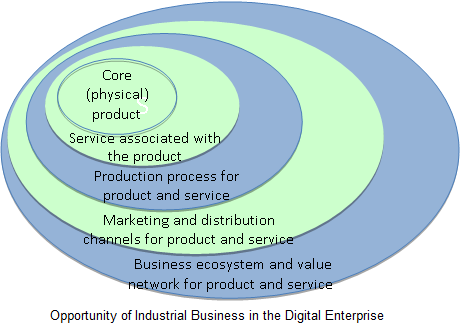

The actual context follows also the trend of shifting from the good-dominant logic to the service-dominant logic, which is best represented by after-sale services (A-SS) or Product-Extension Service (PES) enhancing the utility that the ownership of the product delivers to the customer (e.g. install, configure/tune, repair, maintain and upgrade, take-back etc.) Thus, a new opportunity of Industrial Business arises: the actual customer need leads to the opportunity to create significant added value in customer operations, which aligns also with the perspective of customer-focused production

Business Analytics from Big Data: Optimizing the Decision

Big Data can underpin a substantial wave of gains:

- Improved efficiency in design and production

- Improvements in product quality

- Better meeting customer needs through: (a) more precisely targeted products; (b) effective promotion and distribution; (c) collaborative product development based on customer data.

Big Data can enable 7 performance levers for manufacturers, related to 5 components of the Manufacturing Value Chain:

1. R&D and product design

- Product lifecycle management (PLM): CAD, CAE/CARE, product development management tools, digital manufacturing and more recently digital marketing. Co-create designs with suppliers; Enable experimentations at design stage; Create simulations to test: designs, choice of parts, costs [collaborative use of data for modelling, simulation and controlled experimentation – the Digital Enterprise viewpoint]

- Design to value: extract crucial insights from the increasing volume of customer data to refine existing designs and help develop specifications for new models and variants [customer insights mined from sources: point of sales data, social media, customer feedback, sensor data on product usage]

- Open innovation: outside inputs for innovation through new channels [collaborate on product development via Web 2.0, Web-based platforms]

2. Supply Chain Management

- Advanced demand forecasting and supply planning use own data, integrate data from other sources, include data from retailers (promotion data, launch data, inventory data) [collaborative supply chain management and planning]

3. Production

- Digital factory: used to design and simulate the most efficient production system for a specific product [create a digital model of the entire manufacturing process; Internet of Things applied to the MVC (sensors and actuators within networks of physical objects)]

- Sensor-driven operations: IoT data allows process control and optimization to reduce waste and maximize throughput [embedding real-time, highly granular data from networked sensors in the supply chain and production processes]

4. Marketing and sales

- Use data from customer interactions to: (a) improve marketing and sales; (b) influence product development decisions. Embed sensors in products that can generate data about actual product usage and performance [obtain real-time input on emerging defects and adjust the production process immediately]

5. After-sales

- Shift from GDL to SDL; Collect after-sales data from sensors and feed back in real time:

- Transform the commercial relationship with customers from one in which they sell a product to one in which they sell a service [Product-Service Extensions].

- Use sensor data from products once they are in use to: (a) improve service offerings, (b) create proactive smart preventive maintenance service packages, (c) detect manufacturing and design flaws [Intelligent Products]

Some of the most powerful impacts of big data apply across entire manufacturing ecosystems. Big data plays a pivotal role in ensuring that these ecosystem webs function well and continue to evolve.

Much of the value that big data can create in manufacturing requires the access and varied use of data from multiple sources across an extended enterprise. So to fulfil the potential for value creation in this sector will require production companies to invest in IT as well as to make organizational changes. Other investments will be required to develop interfaces and protocols to share data effectively across the extended enterprise. The standardization of interfaces according to SOA and ESB concepts will be critical and may require industry-wide partnerships to achieve. Strongly departmentalized companies, with multiple IT systems and overlapping and/or redundant data in different operations and divisions, are clearly at a disadvantage. To optimize production planning, data from various tiers of suppliers will be necessary. Demand planning will require customer data from retailers. To access such pools of data, manufacturers will need to be thoughtful about establishing the right value propositions and incentives.

To obtain the benefits of design-to-value, for instance, a company needs to have a free interchange of data among marketing and sales, R&D, and production. So, in many organizations, achieving success will require strong leadership and a cultural shift to establish the mind-sets and behaviours to breech today’s silos. Many organizations will need to undertake organizational change programs to enforce the necessary shift -groups that have never shared their data will not start to do so simply because the IT systems are in place. Many of the levers also require access to data from different players in the value chain.

IBMTEC Workshop topics

- Complexity and Big Data in computing-oriented manufacturing

- Cloud Manufacturing

- Big Data integration and governance for the enterprise

- Virtualization, monitoring and Smart Resource allocation in Cloud Manufacturing

- IBM Cloud Business models

- Monitoring QoS in Cloud Manufacturing

- Business Analytics and optimization in manufacturing decision management

- Predictive Analytics in Manufacturing Value Chain with IBM technologies

- Analytics applications development and integration with IBM Big Data platform

- Manufacturing Integration Framework (MIF) with SOA governance

- The IBM MIF concept and implementing issues

- IBM SOA governance for manufacturing enterprises